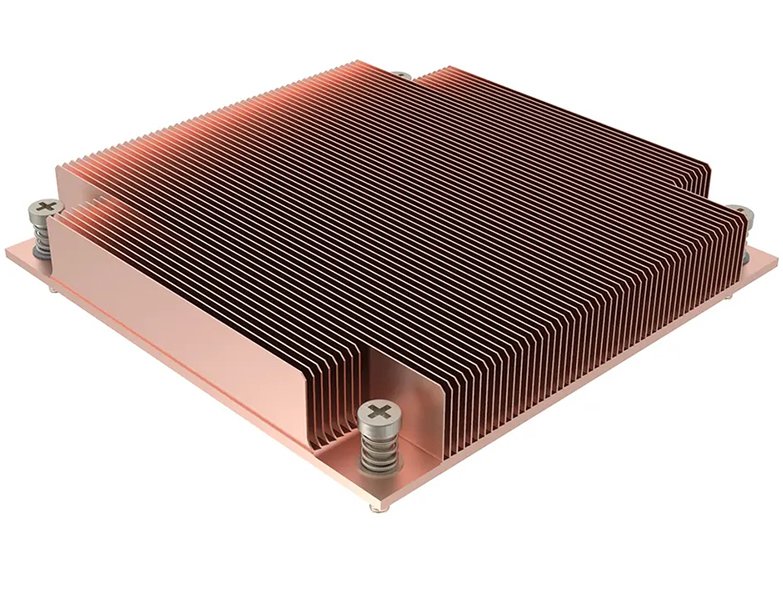

Custom Heat Sink-Skived Fin Heat Sink

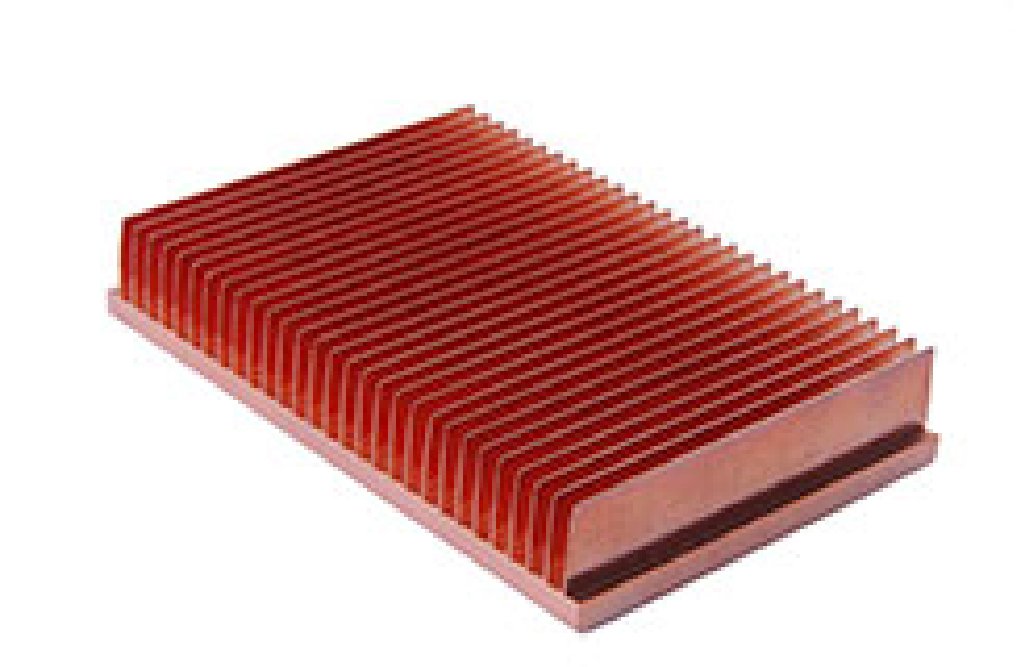

Skived fin heat sinks are advanced cooling solutions used to dissipate heat from electronic components. They're made by cutting thin metal sheets into closely spaced fins, creating a large surface area for heat transfer. This design, achieved through the skiving process, allows for efficient natural convection cooling. Skived fin heat sinks are compact, customizable, and widely used in electronics, aerospace, and other industries to prevent overheating and maintain optimal performance.

Skived Fin Heat Sinks: Next-Level Thermal Management

We specialize in marketing, manufacturing, and managing thermal systems for both custom and standard skived fin heat sinks.

| Material | copper/aluminum 6063/6061/6005/6060/7005. |

| Temper | T3-T8 |

| Production Process | Profiles Extruding—Cutting—CNC Machining(Milling, Drilling, Tapping)—Deburring— Cleaning— In—specting–Packing |

| Technical | extrusion, skived fin, stamping, cold forging, bonded fin, die-cast, liquid cold plates, folded fin |

| Application | LED Lighting, Inverter, Welding Machine, Communication Device, Power Supply Equipment, Electronic Industry, Thermoelectric Coolers/Generator, IGBT/UPS Cooling Systems, etc. |

| Thickness | Based on your requirements. |

| Film Thickness |

Anodized: Customized. Normal thickness: 8 um-25um.

Powder Coating: Customized. Normal thickness: 60-120 um. |

Color | Silver, black, white, bronze, champagne, green, gray, golden yellow, nickel, or customized. |

| Finish | Anodizing, Mill finish, Electroplating, Polishing, Sandblasted, Powder coating, Silver plating, Brushed, Painted, PVDF etc. |

| Length | customized length |

| Deep process | CNC,drilling,milling,cutting,stamping,welding,bending,assembling,Custom Aluminum Fabrication |

| MOQ | Low MOQ |

| Packaging | standard export packaging or as discussed |

| Service | 1. Free sample, Free design. 2. OEM/ODM available. 3. Custom-made request. 4. New design solution suggestion. |

| Delivery time | 15-20 days after sample confirmed & down payment, or negotiated |

| Certificate | CE/SGS/ISO/Rohs |

Premier Supplier and Manufacturer of Skived Fin Heat Sinks

MATERIAL SELECTION

● light

● long life

● corrosion-resistant

● strong and durable

SEAMLESS CUTTING

● polished edging

● smooth surface

● excellent processing

EMPHASIS ON QUALITY

● high quality

● strict testing

● high precision

SUPPORT CUSTOM

● free design

● fast delivery

● provide sample

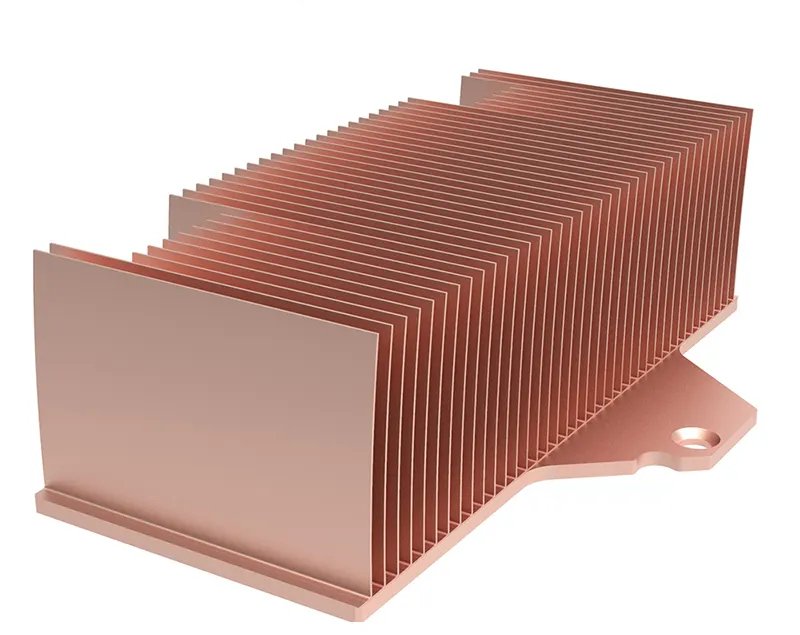

Parts of Our Products

A stacked fin heat sink is a cooling device used to dissipate heat from electronic components. It features vertically stacked thin metal fins that create a high-density arrangement. This design increases the surface area for air to flow through, enhancing heat transfer and cooling efficiency. Stacked fin heat sinks are commonly found in electronics like computers and graphics cards, offering compact and effective passive cooling solutions.

Our stacked fin heat sink showcases cooling base plates on either side, flanking heatsink fins in the center. We specialize in tailored stacked fin heat sinks, available in aluminum or copper, based on your specific needs.

Stacked Fin Heat Sinks

Parts of Our Products

● Efficient Cooling in Vertical Orientation

● Aesthetic Appeal

● Versatility

● Improved Structural Integrity

Our Workshop

send 3D and CAD drawing, confirm production details

confirm the order and start to make samples.

Customization Process

surface treatment confirmation.

send samples to confirm quality and product details

we send the quotation to your for review.

after sample is confirmed, we will start mass production

The Process of Heat Sink Production

Our Packaging

If you seek a proficient skived fin heatsink manufacturer based in China, Tone stands as your ultimate dependable partner!

Our skived fin heatsink leads to an 8% to 15% enhancement in cooling efficiency. Our pioneering approach to skived fin heatsink technology delivers superior performance, increased density, top-notch quality, all while maintaining cost-effectiveness.

Our skived fin heatsinks are crafted using premium-grade aluminum and copper materials. In essence, Tone offers comprehensive, single-piece solutions that eliminate thermal barriers, ensuring optimal cooling performance.

Skived Fin Heat Sinks: Next-Level Thermal Management

● Efficient Heat Transfer: Skived fin heatsinks offer a larger surface area for heat dissipation due to their closely spaced fins, enabling more efficient heat transfer from the source.

● Compact Design: The high fin density allows for compact heatsink designs that are effective in tight spaces, making them suitable for applications with limited room for cooling solutions.

● Customized Geometry: Skiving technology allows for precise control over fin dimensions and shapes, enabling customization to specific thermal requirements and component layouts.

● Improved Cooling Capacity: Skived fin heatsinks can provide higher cooling capacity compared to traditional heatsinks, leading to better thermal performance and component longevity.

● Enhanced Natural Convection: The design of skived fin heatsinks facilitates better airflow between the fins, enhancing natural convection cooling and promoting effective heat dissipation.

● Material Versatility: Skived fin heatsinks can be manufactured from a variety of materials, including aluminum, copper, and more, allowing for material selection based on specific thermal conductivity and weight requirements.

● Cost-Effective Solutions: Due to their efficient design and manufacturing process, skived fin heatsinks often offer a cost-effective balance between performance and production costs.

● Reduced Thermal Resistance: The close fin arrangement minimizes the thermal resistance between the component and the surrounding air, resulting in more efficient heat transfer.

● Wide Application Range: Skived fin heatsinks find applications in various industries, including electronics, automotive, telecommunications, and more, addressing diverse cooling needs.

● Longevity and Reliability: By effectively managing temperature levels, skived fin heatsinks contribute to the extended life and reliable operation of heat-sensitive components, reducing the risk of performance degradation or failure.

At Tone, our skived fin heatsinks come with a unique advantage: zero tooling costs. Each fin is individually cut using the same tool, eliminating the need for additional expenses. Our approach ensures complete customization of the skived fin heatsink to perfectly suit your product's requirements.

For enhanced heat transfer and increased airflow, our skived fin heatsinks can be seamlessly integrated with fans. To optimize the thermal connection, you have the option to include a thermal interface material, offering a comprehensive thermal solution.

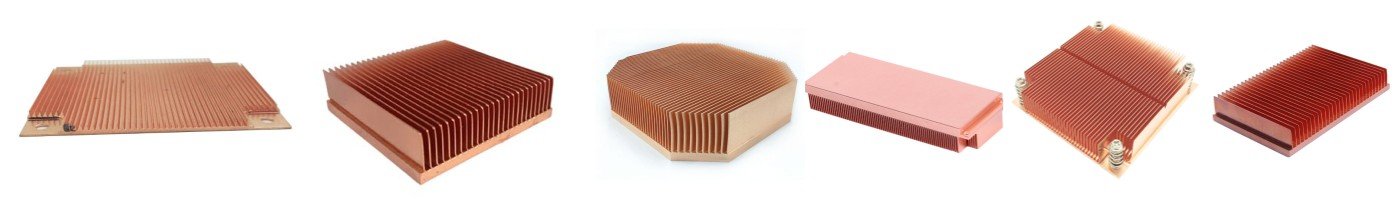

Explore a diverse range of anodized and nickel-plated finishes to complement your skived fin heatsink. We even offer tailored skived heatsinks featuring embedded heat pipes.

Choose from a wide selection of skived fin heatsinks in standard sizes and finishes, readily available in stock for swift shipping. Your heatsink needs are our priority. And if your specifications demand something unique, we can fulfill thousands more sizes of skived fin heatsinks through special orders. At Tone, we've got you covered for all your application and business requirements.

If a custom, one-of-a-kind skived fin heatsink is what you seek, our cutting-edge production facility ensures quick turnarounds without compromising on quality. Reach out to Tone today for comprehensive information and unparalleled solutions.

Skived fin heat sinks are advanced cooling solutions designed to dissipate heat from electronic components, particularly those generating substantial amounts of heat. The term "skived" refers to the manufacturing process used to create these heat sinks. In skiving, thin metal sheets (usually aluminum or copper) are precision-cut into closely spaced, thin fins, which are then integrated onto a base plate. This process results in a heat sink with a high fin density and an increased surface area, optimizing heat transfer.

The primary purpose of skived fin heat sinks is to efficiently manage and redirect heat away from sensitive electronic components, ensuring they remain within safe operating temperatures. The closely spaced fins enable improved airflow and natural convection, allowing heat to dissipate more effectively into the surrounding environment. These heat sinks are used across various industries, including electronics, telecommunications, automotive, aerospace, and more, wherever effective thermal management is crucial. Skived fin heat sinks offer benefits like compact size, customizable design, enhanced heat dissipation, and the potential to increase cooling performance when combined with additional cooling mechanisms such as fans or heat pipes.

What is Skived Fin Heat Sink?

What Are The Benefits Of Skived Fin Heat Sink?

Skived fin heat sinks offer a host of benefits that make them a preferred choice for effective thermal management. Their high fin density ensures efficient heat dissipation, while their compact design accommodates space constraints. Customizable geometry allows tailored solutions for specific cooling needs, and the arrangement of closely spaced fins enhances natural convection cooling. With the flexibility to use various materials, skived fin heat sinks strike a balance between performance and cost-effectiveness. They boast increased cooling capacity, versatility across industries, and contribute to the longevity and reliability of electronic components. Additionally, their compatibility with additional cooling methods like fans or heat pipes further extends their cooling capabilities, making them a versatile and comprehensive solution for managing heat in electronic devices and systems.

The choice of material for a skived fin heat sink depends on several factors, including thermal conductivity, weight, cost, and the specific requirements of the application. Some common materials used for skived fin heat sinks are aluminum and copper, each offering its own advantages:

Aluminum: Aluminum is a popular choice due to its relatively high thermal conductivity, lightweight nature, and cost-effectiveness. It is widely used in various electronic devices and applications. Aluminum skived fin heat sinks are suitable for scenarios where thermal performance needs to be balanced with weight considerations and cost constraints.

Copper: Copper has a significantly higher thermal conductivity compared to aluminum, making it an excellent conductor of heat. Copper skived fin heat sinks are ideal for applications with demanding thermal requirements, high heat fluxes, or where maximizing heat transfer efficiency is critical. However, copper is heavier and more expensive than aluminum, which could impact the overall system design and cost.

The choice between aluminum and copper depends on the specific needs of the application. If heat dissipation is the top priority and cost is less of a concern, copper might be preferable. On the other hand, if a balance between thermal performance, weight, and cost is required, aluminum could be the better choice.

Ultimately, the best material for a skived fin heat sink should be determined by considering factors such as the heat generation of the components, available space, thermal conductivity requirements, budget constraints, and the overall goals of the thermal management solution.

What is The Best Material For Skived Fin Heat Sink?

Skived fin heat sinks are utilized across industries including electronics, telecommunications, automotive, aerospace, LED lighting, medical devices, and industrial equipment. They effectively dissipate heat from components like CPUs, GPUs, power supplies, LED arrays, engine control units, and more. These heat sinks find application in devices ranging from computers, servers, and routers to medical equipment, automotive electronics, and renewable energy systems, contributing to optimal performance, reliability, and longevity by managing heat and preventing overheating-related issues.

Where Can You Use Skived Fin Heat Sink?

The provided parameters outline both the limitations and preferred values for optimizing the cost-efficiency and quality of skived fin heat sinks:

1.The maximum fin height is 100 mm (4 inches), with a maximum fin length of 500 mm (20 inches), while width has no defined limit.

2.To facilitate effective heat dissipation, a minimum fin spacing or gap of 0.1 mm (0.004 inches) is recommended, preventing heat accumulation within the heat sink. This efficient design enhances heat removal, thereby prolonging the lifespan of electronic components and improving performance.

3.For improved performance, the recommended maximum fin spacing or gap is 8.0 mm (0.31 inches), and the ideal fin height remains below 50 mm (2 inches).

4.The materials typically used are copper (C11000) or aluminum (6063/1060), both known for their thermal conductivity properties.

5.For copper fins, an optimal thickness range falls between 0.1 mm and 0.6 mm (0.004 inches to 0.024 inches), while aluminum fins should ideally range from 0.2 mm to 1.2 mm (0.008 inches to 0.047 inches).

In adhering to these parameters, skived fin heat sinks can strike the right balance between cost-effectiveness and high-quality performance, thus ensuring efficient heat dissipation, prolonged electronic component life, and enhanced operational speed.

Which Design Specifications Should You Consider In Skived Fin Heat Sink?

To elevate the efficiency of a skived fin heat sink, optimize its fin design for increased surface area, select materials with high thermal conductivity, employ coatings to improve thermal emissivity, ensure proper airflow through ventilation or fans, utilize effective thermal interface materials, integrate heat pipes for enhanced heat spreading, strategically position heat sinks, experiment with surface modifications like dimples or grooves, and regularly maintain the heat sink's cleanliness. Additionally, consider employing thermal simulation to optimize design configurations virtually, and adhere to optimal operating conditions to achieve optimal heat dissipation, lower component temperatures, and superior system performance.

How Can You Increase The Efficiency Of Skived Fin Heat Sink?

Skived fin heat sinks and pin fin heat sinks are two distinct thermal management solutions, both aimed at dissipating heat from electronic components. Skived fin heat sinks are crafted by cutting thin metal sheets into closely spaced fins attached to a base, resulting in high fin density for efficient natural convection cooling. On the other hand, pin fin heat sinks consist of cylindrical pins attached to a base, offering increased surface area for heat transfer. While they share the common goal of enhancing thermal performance, skived fin heat sinks emphasize high fin density, whereas pin fin heat sinks prioritize increased surface area, and the choice between them depends on factors like space availability and specific cooling needs.

Pin Fin Heat Sink

Is Skived Fin Heat Sink the Same As Pin Fin Heat Sink?

Skived fin heat sinks and bonded heat sinks are distinct thermal management solutions. Skived fin heat sink fins are cut from a single block of metal, usually copper, resulting in high fin density and efficient heat dissipation through natural convection. Conversely, bonded heat sinks are crafted by bonding individual fins into a base, allowing design versatility and material customization. Skived fin heat sinks lack interface joints found in bonded counterparts, facilitating unrestricted heat flow. These differences contribute to skived fin heat sinks having a single-piece construction with lower thermal resistance, while bonded heat sinks, utilizing both aluminum and copper for fins, enhance thermal performance. However, skived fin heat sinks tend to possess higher weight and thicker bases, making them directionally sensitive, whereas bonded heat sinks are often more expensive due to their intricate manufacturing process. Application-wise, skived fin heat sinks excel in compact spaces and high fin density requirements, while bonded heat sinks suit larger-scale applications such as those necessitated by electric welders.