Battery Heat Sink

Bonded Fin Battery Heatsink

Skived Fin Battery Heatsink

Cold Forging Battery Heatsink

Searching for a dependable battery heat sink for your project or enterprise? Look no further! Tone presents an extensive selection of battery heat sinks available for prompt delivery. As your ultimate partner, we specialize in fulfilling your battery heat sink requirements. Our cutting-edge production line ensures top-notch battery heat sinks and complimentary thermal design services. In China, we excel not only as a battery heat sink manufacturer but also as an OEM manufacturer for your brand. Our skilled team is equipped to comprehensively bolster your business with advanced techniques. Get in touch with us today!

Our Workshop

send 3D and CAD drawing, confirm production details

confirm the order and start to make samples.

Customization Process

surface treatment confirmation.

send samples to confirm quality and product details

we send the quotation to your for review.

after sample is confirmed, we will start mass production

The Process of Heat Sink Production

Our Packaging

● Efficient Cooling in Vertical Orientation

● Aesthetic Appeal

● Versatility

● Improved Structural Integrity

Batteries today offer impressive longevity, enhanced power, and a compact form factor, making them suitable for a wide array of devices ranging from smartphones and smartwatches to electric cars and electric-powered aircraft. However, due to their heat generation and power output, batteries often necessitate the use of heat sinks.

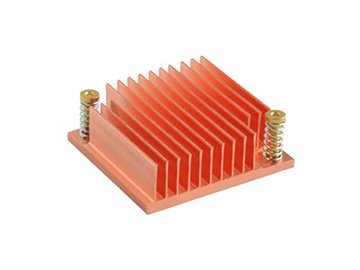

Our battery heat sinks primarily utilize copper and aluminum materials, known for their excellent thermal conductivity. Nevertheless, we can craft our battery heat sinks from various high-conductivity materials. Through conduction, the heat from the battery is efficiently transferred to these heat sinks.

We offer a diverse selection of sizes and shapes for our battery heat sinks. Our manufacturing processes involve intricate techniques such as bonding, cold-forging, CNC machining, skiving, extrusion, stacking, stamping, die-casting, and more, ensuring top-tier quality.

For specific applications, we offer coatings for your Heatell battery heat sinks. Options include anodizing, mill-finish, powder-coating, and custom-tailored solutions to match your specifications. We welcome custom battery heat sink designs—simply provide your requirements.

The surface treatments we provide for our battery heat sinks offer benefits like corrosion resistance, wear resistance, enhanced electrical isolation, and improved surface emissivity. After anodizing, you can even choose from a range of colors including blue, green, black, red, and more.

Whether your needs involve PCB heat sinks, inverter heat sinks, electronic heat sinks, motor heat sinks, amplifier heat sinks, or various other types, we have the expertise to fulfill your diverse heat sink production requirements.

For all your Battery Heat Sink needs, contact us now.