Custom Heat Sink-Extruded Heat Sink

An extruded heat sink is a specialized component designed to manage and dissipate heat efficiently in electronic devices and systems. Engineered through a precision extrusion process, these heat sinks are crafted from materials like aluminum, which offers excellent thermal conductivity. The extrusion method allows for intricate fin designs that maximize surface area for enhanced heat dissipation. Extruded heat sinks play a crucial role in preventing overheating and ensuring the optimal performance and longevity of electronic components by effectively channeling and releasing excess heat.

Elevate Your Heat Dissipation Game with Our Top-Grade Extruded Heat Sinks!

We lead the way in crafting reliable extruded heat sinks. Equipped with 5 advanced automatic extrusion lines ranging from 660T to 4000T, we're geared up to produce sizes of up to 400mm in cross-width.

Our skilled on-site engineers are ready to collaborate from the initial sketch phase, offering insights to en— hance heat dissipation efficiency and address any design vulnerabilities. Count on us for a complete design and manufacturing solution that hits the mark.

Share your extruded heat sink requirements, feel free to contact us. Our commitment rests on delivering cost-effective solutions without compromising on quality.

Advantages of Tone’s Extruded Heat Sink

Our Material Selection

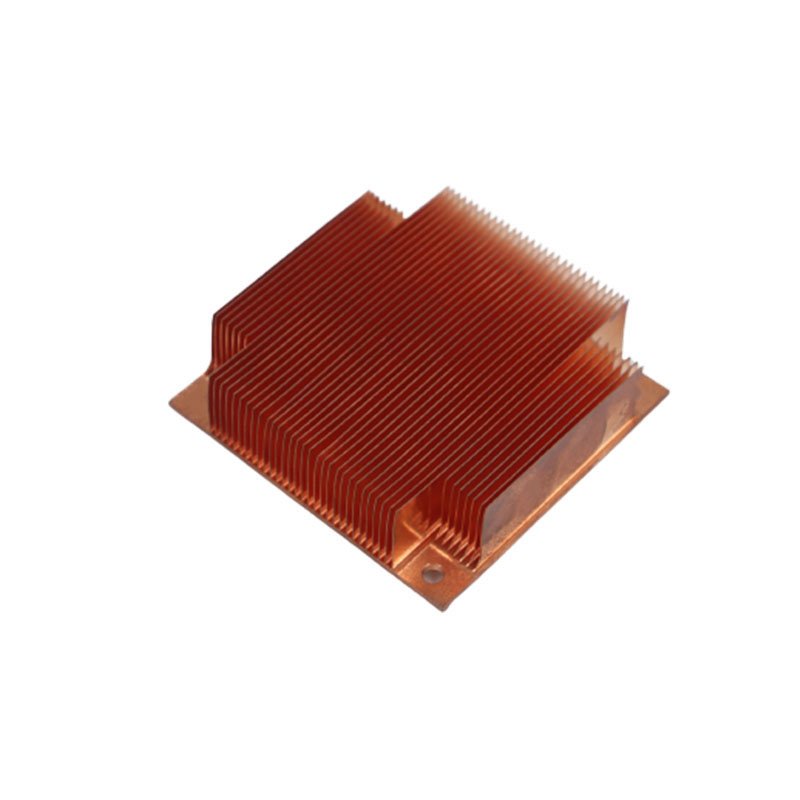

● For Copper

Superior Thermal Conductivity/Efficient/Robust/Premium/Conductive Brilliance

● For Aluminum

Highly Conductive/Lightweight/Durable/Versatile/ Cost-Effective

The choice of material depends on the specific requirements of the application and the desired balance between thermal performance, weight, cost, and other factors.

High—quality Workmanship

● High resistance to stress

● One piece

● Hard to deformed

With a detail-oriented focus, our production process reflects a commitment to V4 Vi flawlessness. From initial design to the final product, every step is characterized by “me, Precision measurements, intricate assembly, and quality checks that leave no room for compromise.

CNC Machine-Smooth Cutting

● Sleek

● Cutting-Edge

● AnodizedOne piece

With a sleek and purposeful aesthetic, our heat sinks seamlessly integrate into a variety of applications. The precisely engineered fins and contours optimize airflow, enhancing heat dissipation efficiency to ensure the longevity and optimal performance of your devices.

What We Can Custom

● Tailored Design Expertise

● Customized Dimensions

● Material Flexibility

When it comes to custom heat sinks, we take pride in offering a comprehensive suite of services and advantages to cater to your specific needs and requirements: Precise Fin Design/ Thermal Analysis/Prototyping/Rapid Turnaround/Collaborative Approach/End-to—End Solution/ Technical Support/Cost-Effective Solutions.

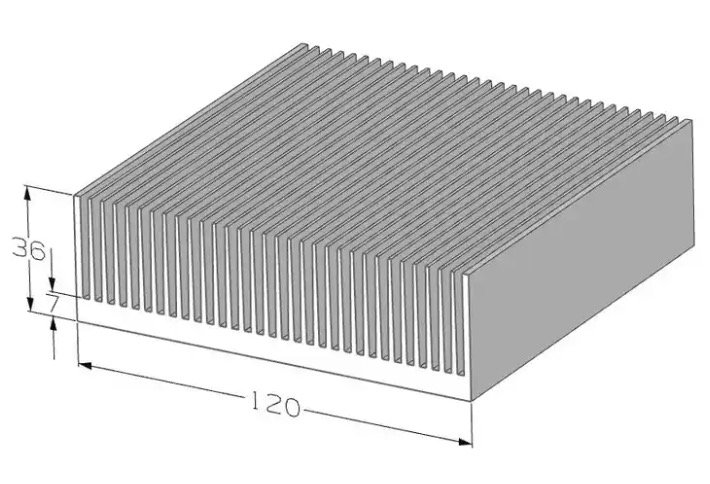

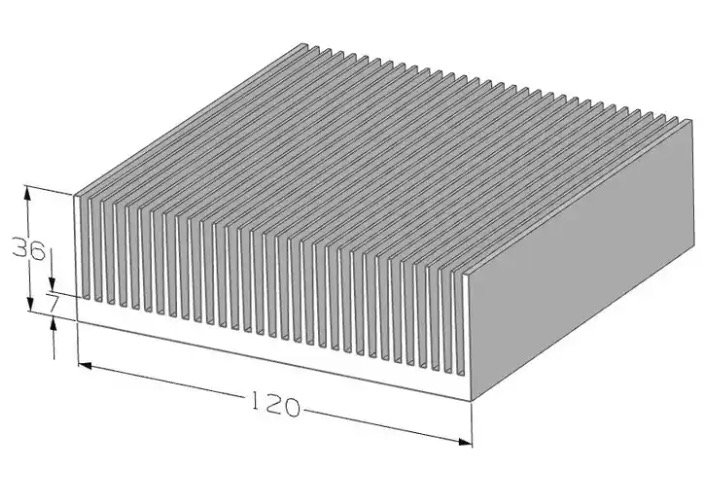

Our extruded heat sinks boast an impressive aspect ratio that can reach 15-20, significantly enhancing their capability for efficient thermal dissipation in demanding applications involving high-power electronics.

Our Workshop

Part of Our Extruded Heat Sinks Solutions

Part of Our Extruded Heat Sinks Solutions

Part of Our Extruded Heat Sinks Solutions

● Efficient Cooling in Vertical Orientation

● Aesthetic Appeal

● Versatility

● Improved Structural Integrity

send 3D and CAD drawing, confirm production details

confirm the order and start to make samples.

Customization Process

surface treatment confirmation.

send samples to confirm quality and product details

we send the quotation to your for review.

after sample is confirmed, we will start mass production

The Process of Heat Sink Production

The Main Advantages of Extruded Heat Sink

We offer the most economical and effective heatsink products made from extruded aluminum.

● Efficient Heat Dissipation: Extruded heat sinks feature intricate fin designs that maximize surface area, facilitating efficient heat transfer and dissipation from electronic components, which helps prevent over— heating and enhances device performance and lifespan.

● Customizable Designs: The extrusion process allows for flexible customization of shapes, sizes, and fin patterns to match specific thermal requirements, ensuring an optimized fit for various applications.

● Cost-Effective Production: Extruded heat sinks can be manufactured in high volumes with relatively lower tooling costs, making them a cost-effective solution for both small-scale and large-scale projects.

● Lightweight Construction: Typically crafted from lightweight materials such as aluminum, extruded heat sinks provide effective thermal management without adding excessive weight to devices or systems.

● Consistent Performance: The uniformity of the extrusion process ensures consistent fin shapes and di— mensions, leading to predictable and reliable heat dissipation performance across all units.

● Quick Turnaround: The streamlined manufacturing process of extrusion allows for rapid production, making it suitable for meeting tight project deadlines and time-sensitive requirements.

● Adaptable to Complex Shapes: Extrusion technology can produce heat sinks with intricate shapes and profiles, enabling efficient cooling in applications where standard cooling solutions may not suffice.

● Integration Possibilities: Extruded heat sinks can be easily integrated with other components, such as heat pipes or fans, to create comprehensive cooling solutions tailored to specific needs.

● Compatibility with Various Industries: From consumer electronics to industrial machinery, extruded heat sinks find applications in a wide range of industries, making them a versatile choice for diverse thermal management needs.

● Sustainable Option: Materials used in extruded heat sinks, such as aluminum, are recyclable, contributing to environmentally friendly practices and sustainability in manufacturing processes.

We offer both standardized and personalized extruded heat sink choices to swiftly optimize solutions for board-level devices. Our focus areas include TO packages, CPUs & GPUs, and BGA/FPGA devices.

Our standard extruded heat sink offers a variety of mounting options and comes equipped with pre—applied thermal interface materials for seamless PCB assembly. The monotone design of our extruded heat sink has gained widespread popularity and is now the preferred choice across diverse industries.

We have been a provider in the following industies:

● Electronics and Technology: From consumer electronics to high—performance computing devices, our heat sinks play a crucial role in maintaining optimal operating temperatures for various electronic compo- nents.

● Telecommunications: Heat sinks are essential for ensuring the reliable operation of networking equip- ment, routers, and communication devices that often generate significant heat.

● Automotive: Heat sinks are used in electronic components within vehicles, including engine control units (ECUs) and infotainment systems, to prevent overheating and ensure optimal performance.

● Industrial Machinery: Our heat sinks contribute to the efficient functioning of industrial equipment, ro— botics, and automation systems, where thermal management is critical. Medical Devices: Many medical devices, such as diagnostic equipment and imaging systems, require ef— fective heat dissipation to maintain accurate operation.

● Renewable Energy: Heat sinks are employed in power inverters and control systems within solar panels and wind turbines to ensure continuous and efficient energy generation. Aerospace and Defense: In aviation and defense applications, heat sinks are utilized in avionics, radar systems, and electronic control units to withstand extreme conditions.

● LED Lighting: Heat sinks are crucial for managing the heat generated by high-power LEDs used in vari- ous lighting applications, ensuring longer lifespan and consistent performance. Consumer Appliances: Home appliances, such as refrigerators, ovens, and air conditioners, benefit from heat sinks to regulate temperatures and maintain energy efficiency.

● Data Centers: Heat sinks are integral in data centers to manage heat generated by server racks and net— working equipment, optimizing performance and energy consumption.

● Telecom Infrastructure: In telecom infrastructure, such as cell towers and base stations, heat sinks aid in maintaining stable and efficient operations.

● Green Technologies: Heat sinks are used in energy-efficient systems like electric vehicles and smart grids to manage heat generated during operation.

Our extruded heat sinks are predominantly crafted using aluminum alloy 6061 and 6063, renowned for their high thermal conductivity. This selection ensures efficient heat dissipation. Moreover, our extrusion process provides these heat sinks with a commendable advantage over copper — notable weight reduction.

Nevertheless, we present you with the flexibility to choose the alloy that aligns with your preferences. Just communicate your desired temper and alloy, and we'll bring it to fruition. With our extruded heat sinks, you're assured of robust attributes tailored to your specific application.

Variety in surface finishes for our extruded heat sinks is a feature we proudly offer. Among these options, the anodized finish stands out as a favorite. Anodization, an electrochemical process, endows our heat sinks with corrosion resistance, surface emissivity, electrical isolation, and enhanced durability.

While coatings like powder or paint aren't viable due to their insulating nature, our extruded heat sinks can be anodized with an array of vibrant hues. Simply share your color preferences, and we'll make it happen.

Should you possess unique prerequisites for your ideal heat sink, rest assured, we're here to bring your vision to life. Alternatively, you can select from our range of standard heat sinks available at our facility. We extend an array of capabilities to ensure your specific surface finish, alloy, and minor operational needs are met. These heat sinks are crafted to order, affording you the autonomy to customize your finishing and alloy preferences.

For added convenience, we maintain stock of our Heatell extruded heat sinks in standard shapes. Our adept sales engineers will guide you to the most suitable shape that closely aligns with your requirements. This eliminates the need for any upfront die costs and offers the possibility of a low minimum order quantity (MOQ) if the product is available in stock.

An extruded heat sink is a component that efficiently dissipates heat from electronic devices. It's made using a process called extrusion, forming fins that increase surface area for better cooling. This helps pre— vent overheating and enhances device performance and longevity.

What Is Extruded Heat Sink?

The most commonly used material for heat sink extrusion is aluminum due to its excellent thermal conduc— tivity, lightweight nature, and ease of extrusion. Aluminum alloys such as 6061 and 6063 are frequently chosen for their balance of thermal performance, cost—effectiveness, and mechanical properties.

Copper is another material with superior thermal conductivity that can be used for heat sink extrusion, es— pecially in applications where maximum heat dissipation is required. However, copper is heavier and gener— ally more expensive than aluminum.

In some specialized cases, materials like stainless steel or even certain plastics might be used for heat sink extrusion, depending on specific thermal and mechanical requirements.

Ultimately, the choice of material depends on factors such as the heat load, thermal conductivity needs, weight constraints, and budget considerations for a given application.

Material For Heat Sink Extrusion?

Aluminum Heat Sink

Copper Heat Sink

How To Select The Best Extruded Heat Sink?

Choosing the appropriate extruded heat sink is a straightforward process. Follow these steps to make an informed decision:

● Utilize Thermal Modules: Employ computer programs to simulate thermal scenarios.

● Analyze Performance: Based on simulations, determine the suitable extruded heat sink for optimal per— formance.

● Design Guidance: Use analysis results as a foundation for designing your specific heat sink. Alternatively, consult the manufacturer for mechanical and thermal models.

● Create Thermal Maps: Develop a detailed thermal map of your application, aiding in precise analysis.

●Informed Decision: With this data, determine if the chosen extruded heat sink aligns with your require— ments.

These coatings provide protection against corrosion, improve thermal conductivity, and enhance aesthetics.

● Anodization: An electrochemical process that forms an oxide layer on the aluminum surface. Anodized coatings offer corrosion resistance, improved emissivity, and electrical insulation. They are available in vari— ous colors and can be dyed for customization.

● Chemical Conversion Coating: This coating forms a protective layer on the aluminum surface, enhancing corrosion resistance and paint adhesion. It's commonly used as a primer before additional coatings.

● Powder Coating: A durable coating applied as a dry powder, then cured to form a protective layer. Powder coatings offer corrosion resistance, electrical insulation, and a wide range of color options.

● Electrostatic Coating: Similar to powder coating, electrostatic coatings provide a durable finish that re— sists corrosion and enhances aesthetics. They are particularly effective for intricate shapes and crevices.

●Ceramic Coating: These coatings are often applied for high-temperature applications, offering thermal insulation and protection against heat and oxidation.

● Electroless Nickel Plating: This process deposits a uniform layer of nickel-phosphorous alloy, enhancing corrosion resistance and providing a conductive surface for improved thermal performance.

● Clear Coating: A transparent protective layer that preserves the natural appearance of the aluminum while providing corrosion resistance.

● Paint: Specialized heat-resistant paints can be applied to the heat sink surface, providing protection against corrosion and enhancing aesthetics.

When selecting a surface coating for your heat sink extrusion, consider factors such as the operating envi— ronment, desired thermal conductivity, aesthetics, and the specific goals of your application. Consulting with experts or manufacturers can help you choose the most suitable coating for your needs.

Surface Coating Options For Heat Sink Extrusion

An extruded heat sink functions as a crucial thermal management component in electronic devices and sys— tems. Its primary purpose is to efficiently dissipate heat generated by high—power electronic components, preventing overheating and ensuring optimal performance and longevity.

Heat Absorption: The heat sink is typically attached to the electronic component, such as a CPU or GPU, through a thermal interface material. This allows for efficient transfer of heat from the component to the heat sink.

Enhanced Surface Area: Extruded heat sinks are designed with numerous fins or ridges that significantly in— crease the surface area available for heat dissipation. The fins create pathways for air to flow through, im— proving convective cooling.

Heat Spreading: Once the heat reaches the heat sink, its high thermal conductivity material, often alumi- num, rapidly spreads the heat across its surface. This spreading helps distribute the heat evenly and pre— vents localized hotspots.

Airflow: As air moves across the heat sink's finned structure, it absorbs the heat, cooling the heat sink. This process is known as convective heat transfer.

Heat Dissipation: The heat absorbed by the air is then carried away, reducing the temperature of the heat sink and the attached electronic component. This cooling effect prevents the component from reaching critical temperatures.

Temperature Reduction: Through the heat sink's efficient heat dissipation, the temperature of the electronic component is lowered, maintaining its optimal operating conditions and preventing potential performance degradation.

Continuous Cycle: The process of heat absorption, spreading, and dissipation continues as long as the electronic component generates heat. This cycle ensures that the component remains within safe tempera— ture limits, contributing to its reliability and longevity.