Custom Heat Sink-Aluminum Heat Sink

An aluminum heat sink is a vital component used for effective heat dissipation in various electronic devices and systems. Made from lightweight yet thermally efficient aluminum material, these heat sinks provide an optimal surface area for heat transfer. Aluminum's excellent thermal conductivity allows it to absorb and disperse heat generated by electronic components such as CPUs, GPUs, and power electronics. By efficiently redirecting and dissipating heat, aluminum heat sinks play a crucial role in maintaining safe operating temperatures and ensuring the reliability and longevity of electronic devices.

Our state-of-the-art manufacturing processes guarantee the meticulous and exceptional crafting of your aluminum heat sink's design.

Aluminum Heat Sink

| Material | Aluminum |

| Temper | T3-T8 |

| Finish | Anodizing, Mill finish, Electroplating, Polishing, Sandblasted, Powder coating, Silver plating, Brushed, Painted, PVDF, etc. |

| MOQ | Low MOQ |

| Application | computer mainboard, PC, IPC, Server, PCTV, Router, Power supply (CPU cooler, VGA cooler, Cooling fan),pico projector, electronic refrigerator, red wine cooler, LASER TV, LCD TV, LED panel, Sound, Air condition, induction cooker, etc.LED lighting,security cameras, infrared light cameras. |

| Deep process | CNC,drilling,milling,cutting,stamping,welding,bending,assembling,Custom Aluminum Fabrication |

| Finish | Anodizing, Mill finish, Electroplating, Polishing, Sandblasted, Powder coating, Silver plating, Brushed, Painted, PVDF, etc. |

| Certificate | CE/SGS/ISO/Rohs |

| Service | 1. Free sample, Free design. 2. OEM/ODM available. 3. Custom-made request. 4. New design solution suggestion. |

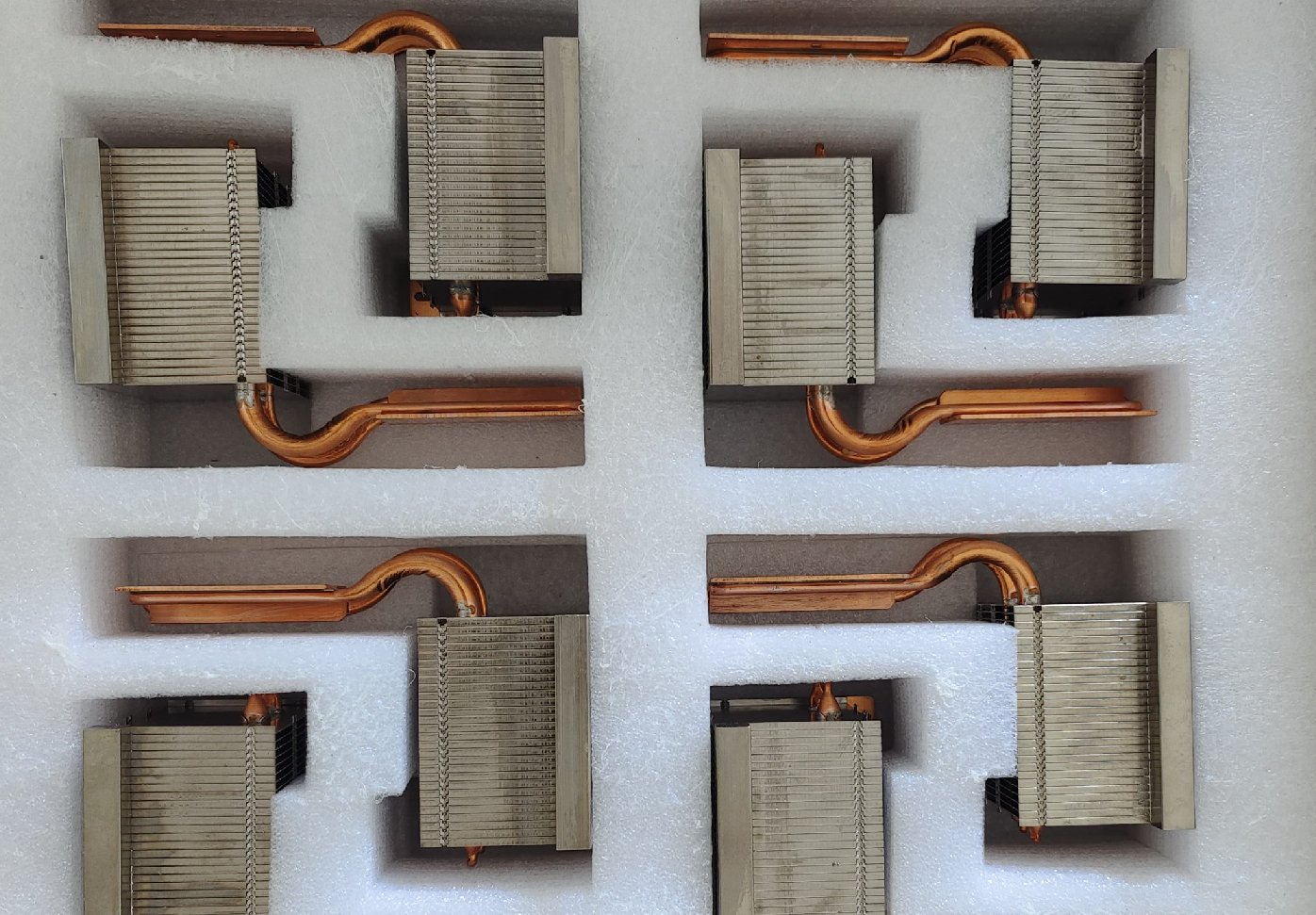

Parts of Our Products

Thermal Design&Thermal Simulation

Our aluminum heat sink gains widespread popularity due to its commendable electrical and thermal conductivity, lightweight yet sturdy construction, remarkable strength, and outstanding corrosion resistance.

● Cost-Effective

● Excellent Corrosion Resistance

● Lightweight and Low Density

● High Thermal Conductivity

Our Workshop

send 3D and CAD drawing, confirm production details

confirm the order and start to make samples.

Customization Process

surface treatment confirmation.

send samples to confirm quality and product details

we send the quotation to your for review.

after sample is confirmed, we will start mass production

The Process of Heat Sink Production

Our Packaging

Aluminum exhibits a higher coefficient of linear expansion compared to other metals. As mentioned earlier, Tone's aluminum heat sinks are remarkably malleable, rendering them essential for applications involving bending, extrusion, and other shaping processes. Tone's aluminum heat sinks are precision-engineered from aluminum 6061 and 6063, boasting a thermal conductivity of 167W/m-K. This exceptional conductivity makes them an optimal choice for both machined and extruded heat sinks. Our diverse range of Tone aluminum heat sinks encompasses BGA Plate Fin Aluminum Heat sinks, DC Plate Fin Aluminum Heat sinks, BGA Round Pin Aluminum Heat sinks, DC Round Pin Aluminum Heat sinks, and BGA Elliptical Fin Aluminum Heat sinks.

An aluminum heat sink is a cooling component designed to dissipate heat generated by electronic devices and systems. It is typically made from aluminum, a metal known for its excellent thermal conductivity and lightweight properties. The heat sink features a finned or ridged structure that increases its surface area, facilitating the efficient transfer of heat from the source (such as a CPU or GPU) to the surrounding air through convection. Aluminum heat sinks are widely used in various applications, including computers, electronic devices, LED lighting, power electronics, and more, to prevent overheating and ensure optimal performance and longevity of components.

What is Aluminum Heat Sink

Aluminum heat sinks are widely used in electronic devices and systems to dissipate heat generated by various components, such as processors, graphics cards, and power amplifiers. The thermal conductive characteristics of aluminum heat sinks play a crucial role in their effectiveness at transferring heat away from the heat-generating components and into the surrounding environment.

● Thermal Conductivity: Aluminum is a highly conductive material when it comes to heat. It has a thermal conductivity of approximately 205-250 W/m·K (watts per meter per kelvin), which means it can efficiently conduct heat from the source (e.g., CPU) to the surface of the heat sink.

● Surface Area: Heat sinks are designed with fins, pins, or other protrusions to increase their surface area. A larger surface area allows for better heat dissipation, as more surface area is available for heat transfer to the surrounding air.

● Design and Geometry: The design and geometry of the heat sink, including the arrangement and size of fins, greatly impact its thermal performance. Different designs are suited for various applications and airflow conditions.

● Base Material and Coatings: Aluminum heat sinks often have a base that comes into direct contact with the heat source. Some heat sinks have copper or other materials at the base due to their higher thermal conductivity. Additionally, some heat sinks may have coatings or treatments to improve their surface properties and enhance heat transfer.

● Contact Interface: The interface between the heat sink and the heat source (e.g., CPU or GPU) should be optimized for efficient heat transfer. Thermal interface materials (TIMs), such as thermal paste or pads, are used to fill any microscopic gaps and ensure good thermal contact between the two surfaces.

● Airflow: Heat sinks rely on the movement of air to carry away the heat. Natural convection, forced convection (with fans), or a combination of both can be used to enhance heat dissipation.

● Mounting and Pressure: Proper mounting pressure is crucial to ensuring good contact between the heat sink and the heat source. Insufficient pressure can lead to air gaps and reduced heat transfer efficiency.

● Thermal Resistance: The thermal resistance of a heat sink is a measure of how effectively it can transfer heat. Lower thermal resistance indicates better performance. It's important to consider the overall thermal resistance of the entire system, including the heat sink, thermal interface materials, and any other components.

● Material Choice: While aluminum is commonly used due to its balance of thermal conductivity, cost, and lightweight nature, other materials like copper offer higher thermal conductivity. The choice of material depends on the specific requirements of the application.

● Temperature Gradients: A well-designed heat sink should minimize temperature gradients across its surface, ensuring even heat distribution and dissipation.

Thermal Conductive Characteristics of Aluminum Heat Sinks

Aluminum heat sinks are widely used in electronic devices and systems to dissipate heat generated by various components, such as processors, graphics cards, and power amplifiers. The thermal conductive characteristics of aluminum heat sinks play a crucial role in their effectiveness at transferring heat away from the heat-generating components and into the surrounding environment.

Material Selection and Design:

ㆍChoose high-conductivity aluminum alloys like 6061 or 6063, which have good thermal conductivity.

ㆍOptimize the fin density and spacing. Increasing the surface area of the fins improves heat dissipation.

ㆍUse larger fins and a larger overall surface area to enhance heat transfer.

Finned Geometry:

ㆍUse different fin shapes, such as straight fins, pin fins, or louvered fins, to enhance the heat transfer surface area and improve airflow.

ㆍOptimize the aspect ratio (height-to-thickness ratio) of the fins. Increasing the aspect ratio can improve heat transfer while maintaining structural integrity.

Surface Treatment:

ㆍApply coatings or finishes to enhance emissivity and promote radiation heat transfer.

ㆍConsider using anodizing or other surface treatments to improve corrosion resistance and thermal emissivity.

Thermal Interface Materials (TIMs):

ㆍUse high-quality thermal interface materials between the heat sink and the heat source (e.g., a semiconductor device). This ensures efficient heat transfer between the surfaces.

ㆍConsider using thermal pads, thermal paste, or phase-change materials for better heat conduction.

Airflow Management:

ㆍEnsure proper airflow around the heat sink. Position the heat sink in a way that maximizes exposure to natural or forced convection.

ㆍIncorporate features like shrouds or ducts to guide and optimize airflow through the fins. Forced Convection:

ㆍUse fans or blowers to enhance forced convection across the heat sink fins. Proper fan selection and placement are critical for optimal performance.

ㆍDesign the fins to be conducive to efficient airflow.

Heat Pipe Integration:

ㆍIncorporate heat pipes into the heat sink design to enhance heat transfer across the fins. Heat pipes are particularly effective for spreading heat over larger distances.

Optimize Heat Sink Size:

ㆍMatch the size of the heat sink to the thermal requirements of the application. Oversized heat sinks can be inefficient and costly.

Computational Fluid Dynamics (CFD) Analysis:

ㆍUse CFD simulations to model and optimize the heat sink's performance. This can help in identifying potential areas of improvement in the design.

Multi-Layer Heat Sinks:

ㆍConsider using multi-layer heat sinks with different fin sizes to optimize heat dissipation across various temperature gradients.

Temperature Sensors and Feedback:

ㆍIncorporate temperature sensors on the heat sink or the heat-generating components. Use this data for real-time feedback and control of the cooling system.

Maintenance and Cleaning:

ㆍRegularly clean the heat sink from dust and debris that can hinder airflow and reduce efficiency.

Strategies for Improving the Thermal Efficiency of Aluminum Heat Sinks

Types of Aluminum Alloys For Fabricating Aluminum Heat Sink

ㆍAluminum Alloy 1050 with thermal conductivity of 229 W/M-K

ㆍAluminum Alloy 6060 with thermal conductivity of 166 W/m-K

ㆍAluminum Alloy 6061 with thermal conductivity of 152 W/m-K

ㆍAluminum Alloy 6063 with thermal conductivity of 201 W/m-K

Material and Quality:

ㆍThe choice of aluminum alloy affects the cost. High-conductivity alloys like 6061 or 6063 tend to be more expensive.

ㆍThe quality and purity of the aluminum used can impact the heat sink's thermal performance and overall cost.

Size and Complexity:

ㆍLarger heat sinks generally cost more due to the increased material usage.

ㆍComplex designs with intricate fin patterns, multiple layers, or custom shapes require more precise manufacturing processes and may be more expensive.

Manufacturing Process:

ㆍThe manufacturing method used can significantly affect the cost. Extrusion is generally cost-effective for simple designs, while processes like CNC machining or die casting can be more expensive but offer higher precision and customization.

Fin Density and Complexity:

ㆍA higher fin density or complex fin geometry can increase the manufacturing complexity and therefore the cost.

Surface Treatment and Coatings:

ㆍAdditional surface treatments such as anodizing, coating, or finishing can enhance thermal performance and corrosion resistance but may add to the cost.

Quantity Ordered:

ㆍOrdering heat sinks in bulk can often lead to volume discounts, reducing the unit cost.

Customization:

ㆍCustom heat sink designs, including unique shapes or branding, can increase the cost due to design and tooling expenses.

Additional Features:

ㆍAdditional features like integrated heat pipes, mounting mechanisms, or thermal interface materials can impact the cost.

Supplier and Brand:

ㆍEstablished brands or reputable suppliers might have higher prices due to perceived quality and reliability.

Market Demand and Competition:

ㆍSupply and demand dynamics in the market can influence prices. If aluminum is in high demand or if there's limited competition, prices could be higher.

Labor and Overhead Costs:

ㆍLabor costs, overhead expenses, and geographical location of the manufacturer can affect the final price.

Packaging and Shipping:

ㆍPackaging and shipping costs can add to the overall price, especially for large or fragile heat sinks.

Certifications and Compliance:

ㆍHeat sinks designed for specific industries or applications might need to adhere to certain certifications or compliance standards, which could affect the price.